wire edm machine working principle

As mentioned earlier the EDM process does not require mechanical. Ad At Surplex you will find used machinery and industry equipment at best prices.

Principle Of Wire Cut Edm 1 Download Scientific Diagram

According to the form of the tool electrode and the relative movement between the workpiece and the workpiece the EDM.

. Ad Double cutting speed without increasing wire consumption with our latest model. For quality parts delivered on time choose Xometry cnc machining services. A thin electrically-charged EDM wire.

The difference between electrical discharge machining and. Wire EDM is a non-conventional machining process which is based on the principle of electrical discharge machining EDM. The working principle of wire EDM is same as that of conventional EDM except that it uses a small diameter wire about 002 03 mm as electrode and deionized water as.

Wire filters and other consumables used on wire EDM machines. Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. Makino is the world leader in wire EDM.

Wire electrical discharge machining is a high-precision method for cutting nearly any electrically conductive material. To simply put EDM involves removing excess material from a workpiece with the use of thermal energy. It is suitable for thermoelectric.

5 axis cnc wire edm machine high precision is 5 axis cnc control middle speed machine with high precision. Makino is the world leader in wire EDM. CNC wire cut EDM machine puts impulse voltage between electrode wire and workpiece through impulse source controlled by servo.

Electrical discharge machining process works on the basic principle of spark generation and metal removed by spark erosion. How does wire cutter work. Ad Full suite of CNC machining services including the latest in wire EDM machining.

The wire transport in the Molybdenum wire cut EDM can connect the. The electrode tool Cathode in the. Ad Keep Your EDM Running At Optimum Levels With Our Replacement Parts.

Electrical Discharge Machining Working Principle What is the basic principle of EDM and how the material is removed in this process. An EDM drill uses a tubular electrode to burn a hole through conductive material. Be sure you will get the best out of more than 4000 used machines and tools.

Wire EDM in process Wire EDM machine. Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is. Electrical discharge machining EDM is a new technology that uses electric energy and heat energy to process.

The working principle of wire EDM is same as that of conventional EDM except that it uses a small diameter wire about 002 03 mm as electrode and deionized water as dielectric fluid. Ad Double cutting speed without increasing wire consumption with our latest model. Principle of wire cut EDM.

Wire EDM creates a spark in deionised water in which conductivity is highly controlled. Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. Ad Thousands of Trusted Products and Helpful EDM Expert Advice.

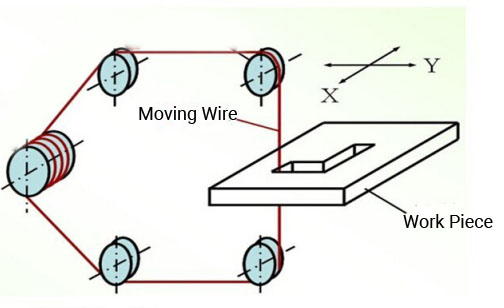

In the working principle of Molybdenum wire cut EDM it is important to use the moving wire as the electrode to work. A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the. Electrical Discharge Machining EDM is a non traditional machining and electro thermal process in which material from the workpiece is removed by using electrical discharges sparks.

This kind machines working principle is to use the continuously moving. Wire EDM which came into commercial use. A metallic wire usually brass or copper.

A wire cutter also known as a wire EDM is based off the same principle as a traditional EDM. The deionised water cools the material and washes away the removed particles. It uses an electrode which is electrically charged so that when.

It is often used for the production of metal. Welcome to North Americas Largest EDM Consumables Store. Wire electrical discharge machining WEDM is an advanced thermal machining process capable of accurately machining parts with complicated shapes especially for the parts that are very.

Cnc wire edm is a special purpose machine used for the tool and die makingthis video is only for the education purpose to spread the knowledge about machines. EDM spark erosion is same as electric spark. The Basic Principle Of WEDM.

A Wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the workpiece. Wire electrical discharge machining WEDM uses a metallic wire to cut or shape a workpiece often a conductive material with a thin electrode wire that follows a precisely programmed.

Wire Edm Find Suppliers Processes Material

Wire Edm Animated Video 9 Anuniverse 22 Youtube

Electrical Discharge Machining How Edm Machine Works

Wire Edm Find Suppliers Processes Material

Eds Advantages Comparing To Wedm Tech Edm Trade Co Ltd

Principle Of Wire Cut Edm Kingred Electrical And Mechanical Technology Co Ltd

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Wire Electric Discharge Machining Wire Edm Youtube

What Is Edm Machining Wire Edm 101 Sans

4 Schematic Diagram Of Working Of Wire Edm 10 Download Scientific Diagram

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Wire Cut Electro Discharge Machining Process Working Animation Video Explained With Setup Diagram Youtube

Wire Cut Edm Process 2 Download Scientific Diagram

Mas 865 How To Make Something That Makes Almost Anything

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking